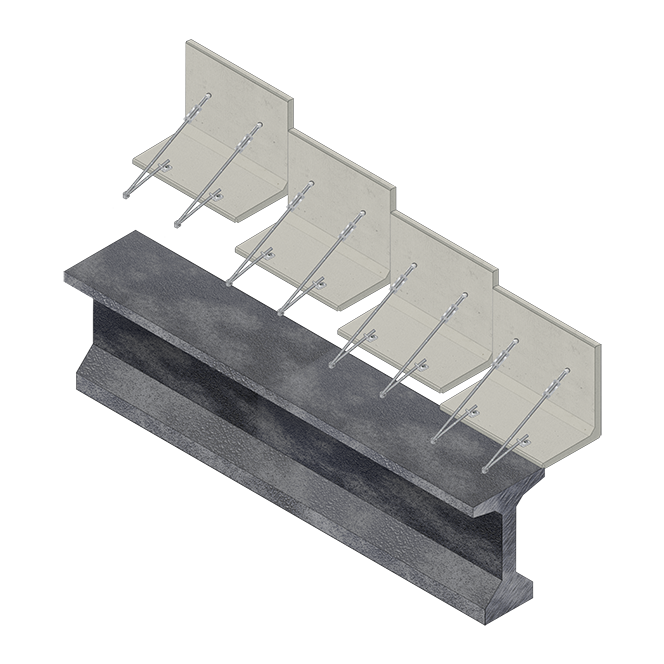

Bridge Overhang Construction Just Got Easier

Eliminate inefficiency and waste in your bridge overhang construction projects. Precasteel’s StayPanel™ stay-in-place concrete forms can save money, cut project time in half, and extend the service life of your bridge.

Learn More

A Game-Changing Product

Precasteel’s StayPanel™ forms beat conventional bridge brackets on every level.

Easy Installation, Lasting Results

The sleek design of StayPanel™ forms makes them easy to install and makes your bridge more aesthetically pleasing.

A Proven Track Record and Promising Future

StayPanel™ was the formwork of choice for the $8 billion LaGuardia Airport terminal replacement, paving the way for other high-profile projects.